Time for a er8 update! Lots of new tools and race car development capability for us, some good news, and some not so good news.

We're intending to use the er8 project to develop tools, design principles, and specialist products where needed.

Good news!

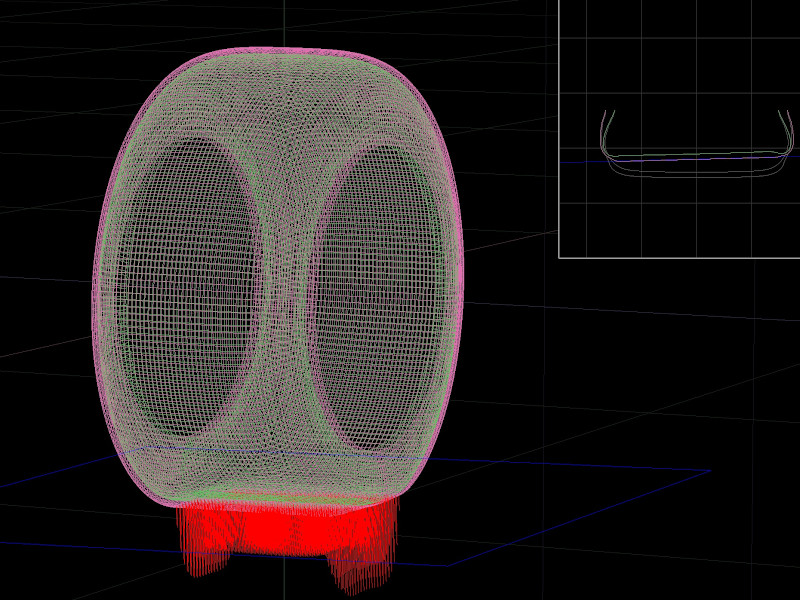

The biggest tool development has definitely been in cfd. We really looked though our whole CAD-to-CFD results pipeline, all the components of that, where to fix issues for the whole thing to run as efficiently as possible, and also automated the calculation system to give us a sweep of ride heights, yaw angles, and pitch angles. Computation speed has also hugely improved. A single cfd case back when we started our er8 project took around 22h to run. Now we get a complete sweep run in approximately 16h, while using a much finer and larger mesh. Crazy how quickly we can iterate designs now! We even have a clear path to improve that further if we need to.

This improved efficiency has allowed us to understand the airflow and especially ground effect interaction much better than before. Allowing us to design a "blown aero" exhaust setup, and also maintaining very good stability. Resulting in unheard of downforce and performance values for the er8. This has however come at a cost.

Downforce numbers are so high that the large 310/710mm 18inch slicks that we had selected for the car may no longer be big enough. Huge downforce at high speeds just end up compressing the side walls too much. And these forces are so high that slight tweaks to tire pressures don't help much. We're now in a situation where we either need to redesign the bodywork and suspension to run even larger diameter (and maybe also wider) tires that the 310/710, or we need active tire pressure control. It looks like 3 or 4 bar tire pressure would be enough to keep the side walls from folding over themselves too much at high speeds. But this is much too high of a pressure for low speed corners, where the er8 is so light that we would probably want to run sub-1bar tire pressures.

Active tire pressure would be less work to implement not needing the complete car redesign that larger tires would, and would also be the much safer option. The car's electronics can take immediate action in case of a tire failure, or slow leak or similar situation.

With a car this fast, safety is something we take very seriously.

Not yet news

We're also very close to the release of a new product that we needed to develop for our er8. This is to rigidly attach (even preload if needed) rigid body components together while having a big load bearing capability, and adjustability to line parts up perfectly. But more on that in the future when be launch it!

The not so good news

As you might have guessed, the tire situation has made it impossible for us to have the car at wtac 2023. It's doubtful if we even with more time to develop a active tire pressure system would be capable of running at wtac with the current tire size limitations (much smaller than 310/710 for a car as light as the er8). Without us either limiting top speed to below 250km/h (which would look ridiculous and not put on a good show) or designing the car to produce less downforce, which we of course don't want to do since we want maximum performance at other events.

We will be in close contact with the wtac event organizers and see if we could come up with some way to allow big enough tires for us to be able to safely compete at WTAC 2024. In the mean time we will of course be rooting for Rod Pobestek and his ElmerRacing Thor powered RP968 at WTAC 2023. Which has to be the pre-race favorite?

TimeAttack events here in Europe don't have tire size limitations in the top category, so there should be no shortage of events to race at with our er8 anyway. But we naturally would want to be at the premier world championship event also at some point.

Unfortunately that time will not yet be in 2023.